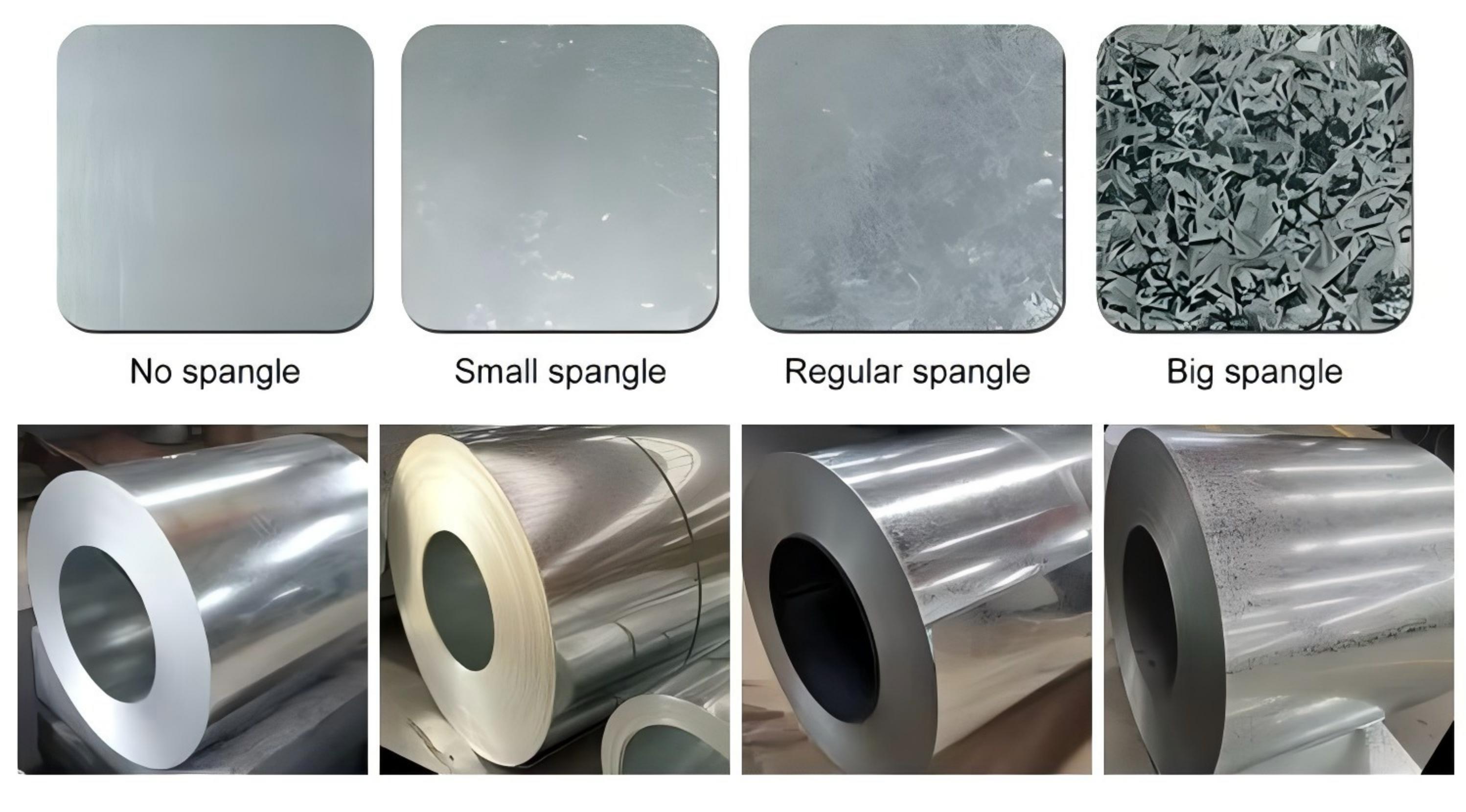

The smooth surface and extraordinary brightness of galvanized steel coils make them a popular choice for the manufacture of sheets, tubes and pipes. We offer cold rolling, hot rolling and extrusion procedures to produce galvanized steel coils according to your desired thickness, size and shape. Our coils are known for their low inclusions, pure steel composition, high dimensional accuracy and stable chemical composition. Simply provide us with your requirements and we guarantee high quality products with a wide range of grades and different surface finishes to meet your needs.

Hot dip galvanized steel coil, the thin steel plate is dipped into the molten zinc tank, so that the surface is attached to a layer of zinc thin steel plate. At present, the continuous galvanizing process is mainly used for production, that is, the rolled steel plate is continuously immersed in the galvanizing bath with molten zinc to make galvanized steel plate; Alloyed galvanized steel sheet. This steel plate is also manufactured by hot dipping, but immediately after leaving the tank it is heated to about 500 ° C to form an alloy film of zinc and iron. This galvanized coil has good paint adhesion and weldability.